AUTOMOTIVE BATTERY MANAGEMENT SYSTEMS

The battery management systems designed by ME play a crucial role in optimizing the performance and longevity of EV batteries. These advanced systems ensure efficient charging, discharging, and monitoring of battery safety and health, maximizing the overall efficiency and range of electric vehicles.

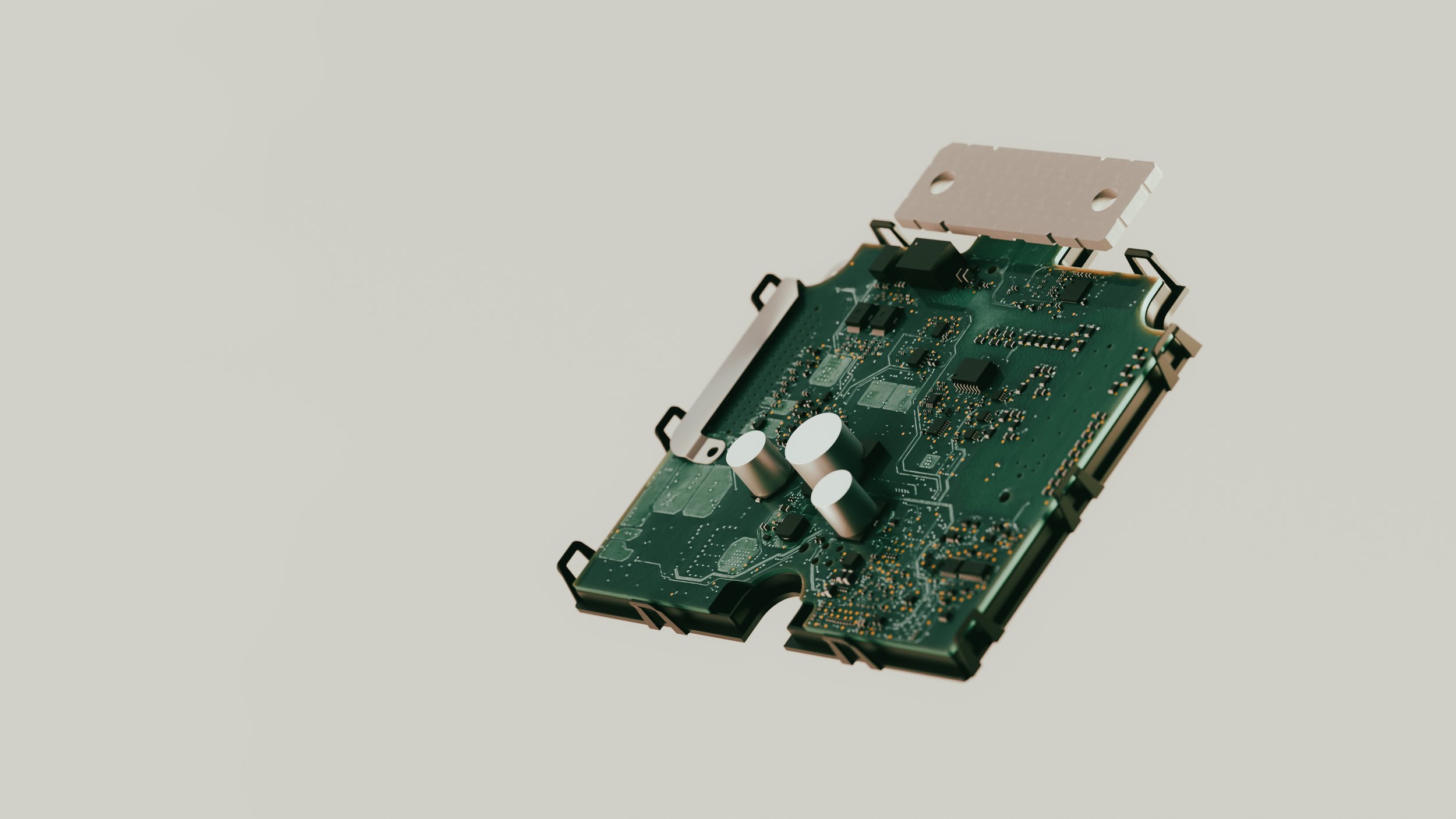

BARCELONA SBS –

SMART BATTERY SENSOR

The SBS is an integrated battery management control unit. It combines an accurate current sensor with a high performance battery management control unit.

The control unit contains all features you would expect from a modern automotive BMS as well as some unique additional functionalities.

HIGHLIGHTS OF THE BARCELONA SBS FEATURES:

Integrated, dual-shunt current sensor with rapid overcurrent detection

Pyro fuse driver with backup energy storage

Up to 8 high voltage measurement channels

Active and passive isolation monitoring

Contactor drivers with fail-operational mode allowing for maximum availability

Interface to Cell Monitoring Boards and additional sensors

Over-the-air update functionality and remote monitoring is enabled in combination with our telematic control unit

Fully configurable modern BMS software stack with cyber security ISO21434, ISO26262- compliant functional safety up to ASIL D and OBD compliance

PRODUCT FLYER BARCELONA SMART BATTERY SENSOR

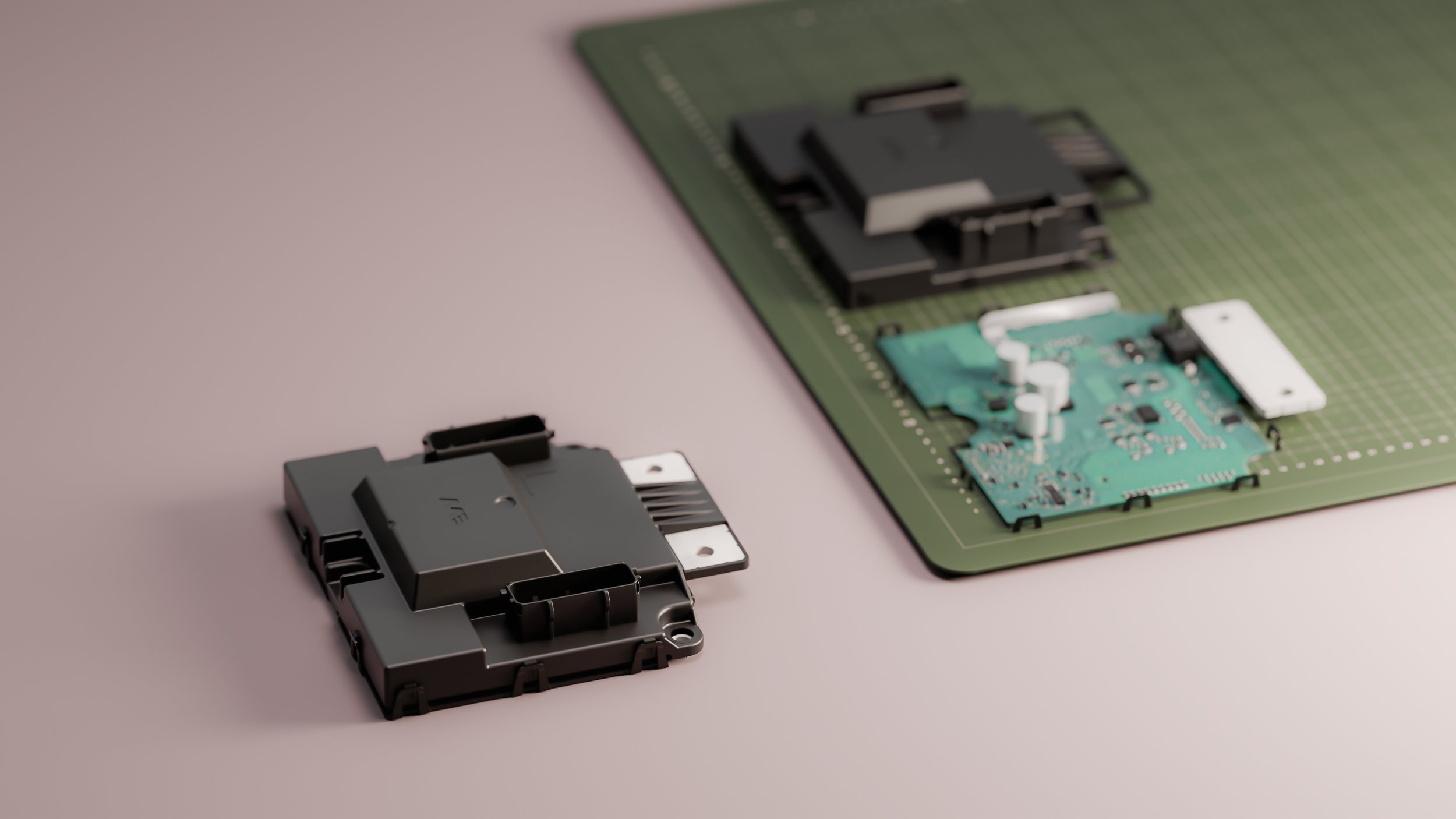

BOLOGNA BATTERY MANAGEMENT UNIT

ISO26262 Certification on Product Level: The Bologna Battery Management Unit is ISO26262 certified and supports both 12 V and 24 V supply voltages. Additionally, it is designed to accommodate 400 V / 800 V switching architectures. This product caters to a diverse range of applications, including but not limited to PC, CV, LCV, marine, ESS, motorsports, or buses.

Advanced Functionality: Featuring main / peripheral coordination logic at the pack level, the Bologna Battery Management Unit allows for the configuration of up to 8 contactors and 8 HV measurement inputs. This ensures flexibility and adaptability for various system requirements.

HIGHLIGHTS OF THE BOLOGNA FEATURES:

In production since Q1 2019. Field experience in various applications

Flexible BMS platform with versatile feature set

Different cell chemistries and module sizes are supported

Completely inhouse developed BMS platform

Patented ME safety concept. ISO26262 compliance up to ASIL C

Multi-string and multi-pack state control capability

(up to 950 V, up to 32 BMUs)SW architecture allows quick adaption of battery pack architecture

and vehicle interfaceChoose from a wide range of SW functionalities including J1779, J1939, J1979 and Thermal Event detection

PRODUCT FLYER BOLOGNA BATTERY MANAGEMENT UNIT

CMB –

CELL MONITORING BOARDS

Munich Electrification offers a variety of tailored CMB solutions. While 12 and 18 channel versions are available off-the-shelf, ME customers benefit from highly integrated customized CMB versions specifically optimized for each application.

HIGHLIGHTS OF OUR CMB PORTFOLIO:

High cell voltage measurement accuracy

Precise cell temperature input measurement channels

Innovative additional sensors for thermal event detection

Compact design with integration features ranging from flex circuit interface to fully cellmodule-integrated CMBs

Functional Safety levels up to ASIL D in combination with the SBS

Various cell voltage measurement channel counts possible

Utilization of advanced cell monitoring chipset technology

PRODUCT FLYER CELL MONITORING BOARD

wCMB –

WIRELESS CELL MONITORING BOARD

ME offers a wireless cell monitoring board (wCMB). This product allows the integrator to get rid off all communication harnesses within the battery pack. Maximum flexibility and re-usability of modules can be achieved with this technology. Immersion cooled battery packs benefit from the wireless communication in particular, as sealed cable interfaces are removed.

THE HIGHLIGHTS:

High cell voltage measurement accuracy

Functional Safety and Security certified wireless communication technology

Weight and cost savings on pack level due to reduced wiring and connectors

Increased reliability due to reduced number of interconnects

wCMB can be integrated with the SBS

PRODUCT FLYER WIRELESS CELL MONITORING BOARD

HIGH-VOLUME

AUTOMOTIVE PRODUCTION

We combine the capabilities of fast and agile inhouse prototyping with the quality, scalability and global footprint of our strong production partners. Our robust APQP process in accordance with VDA and AIAG regulations enables to succeed with challenging timelines in a fast moving environment.

Our strategic production partners with long-standing manufacturing experience of complex automotive electronics allow for global high-volume projects and fully comply with all regulatory standards and processes including IATF-16949, ISO-9001 and ISO-14001.

We develop our own manufacturing technology, backend solutions for sub-system assembly and functional end-of-line test systems for traceability. As a specialized automotive electronics company, we focus on stringent supply chain management and comprehensive risk management to ensure quality, delivery capability and availability at all points in the product lifecycle.

GET IN TOUCH

If you would like to know more about these products, feel free to contact us.